The Journey of Each Pot

Our functional pottery is created thoughtfully and with care through the entire making process.

Wedged

We use a two different clay bodies to create our work, each providing a unique texture and finish.

Thrown

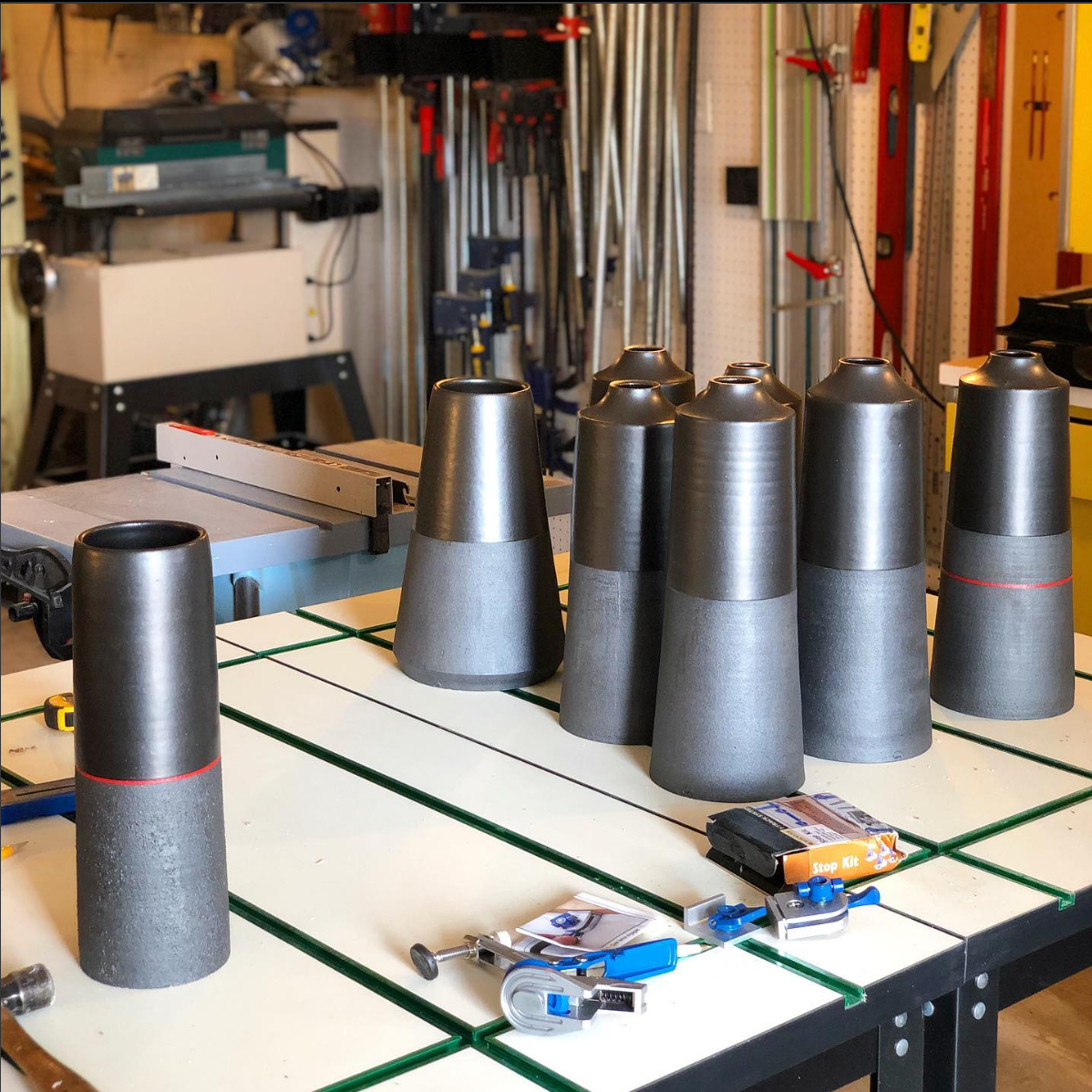

Every vessel is hand-thrown on the potters wheel in our Golden, Colorado studio. Each pot is thrown to exact specifications of form and size.

Dried & Trimmed

Vessels are slowly dried before they are trimmed. After that they are allowed to dry fully. This is a slow and thoughtful process.

Bisqued

Dried pieces will make their way through the initial bisque firing - the first of two before they are complete.

Glazed

Our underglazes are all hand-brushed on the potters wheel with extreme precision or dipped before making their way to the next firing.

Fired

Pots undergo their next firing in a gas kiln at Cone 10, ensuring Fenway's vivid, saturated colors and a lifetime of durability.

Turned Wood

After the ceramic lamp or jar is completed, it is finished with lathe-turned wood components, perfectly crafted to match the form of it's ceramic counterpart.

Finishing Touches

Lamps are assembled and fitted with harps, hand-turned wood finials, hand-made shades, fabric wrapped cords, and dimmable LED bulbs.

The bottom of all other vessels are sanded to ensure a smooth finish.